The reciprocating gas compressors are used to create a low-pressure area in the compression chamber when the piston moves from the highest stroke point to the lowest stroke point. In these compressors the gaseous products moves into the compression chamber at a higher pressure and this volume of gas is then displaced when the piston moves to the top of stroke.

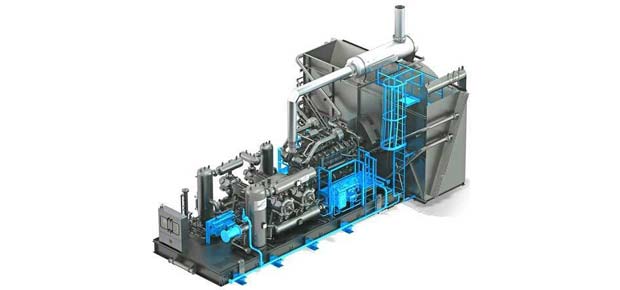

Reciprocating gas compressors are designed with high efficiency valves, self-adjusting piston rod seals, ductile iron cylinders, and a host of other robust features, to provide optimum performance and reliability under the most severe operating conditions.

Design

In the body of a compressor, there are 2 screws with mating profile - a

male (with convex helical inlets) and a female screw (with concave inlets).

The screws rotate in opposite directions with the female screw receiving the

driving power and transmitting it to the male screw using a set of

synchronization gears.

As the 2 screws rotate, the air is drawn into the inlet port and fills up the gap between the screws. This phase is known as the admission and the key phase is the compression, which starts when the end of a male thread blocks female thread end. The volume that is available between the body of compressor and these two threads then progressively decreases during rotation. When this gap merges into the delivery outlet of the compressor, the third phase takes place, which is known as the exhaust.

Throughout this process, the 2 screws do not contact even for a single interval, which means zero wear, complete reliability and non-pulsating air delivery. The blowers / compressors can be used in either a mobile or stationary application and can be driven by an electric motor or a hydraulic power system. A complete range of ancillary products is designed to support this product line.

Applications

If you have decided to make soap at home, you will need soap making supplies in the form of raw materials, soap making equipment & tools ...

Read More

Someone has rightly said that clothes are not just clothes. They form an integral part of a person's personality and tell a lot about their nature and...

Read MoreCleansing products play an important role in the daily lives of people.

Both soaps and detergents are cleansing products that we frequently use in our

Soap is designed as a product to be used once and then flushed down the drain...